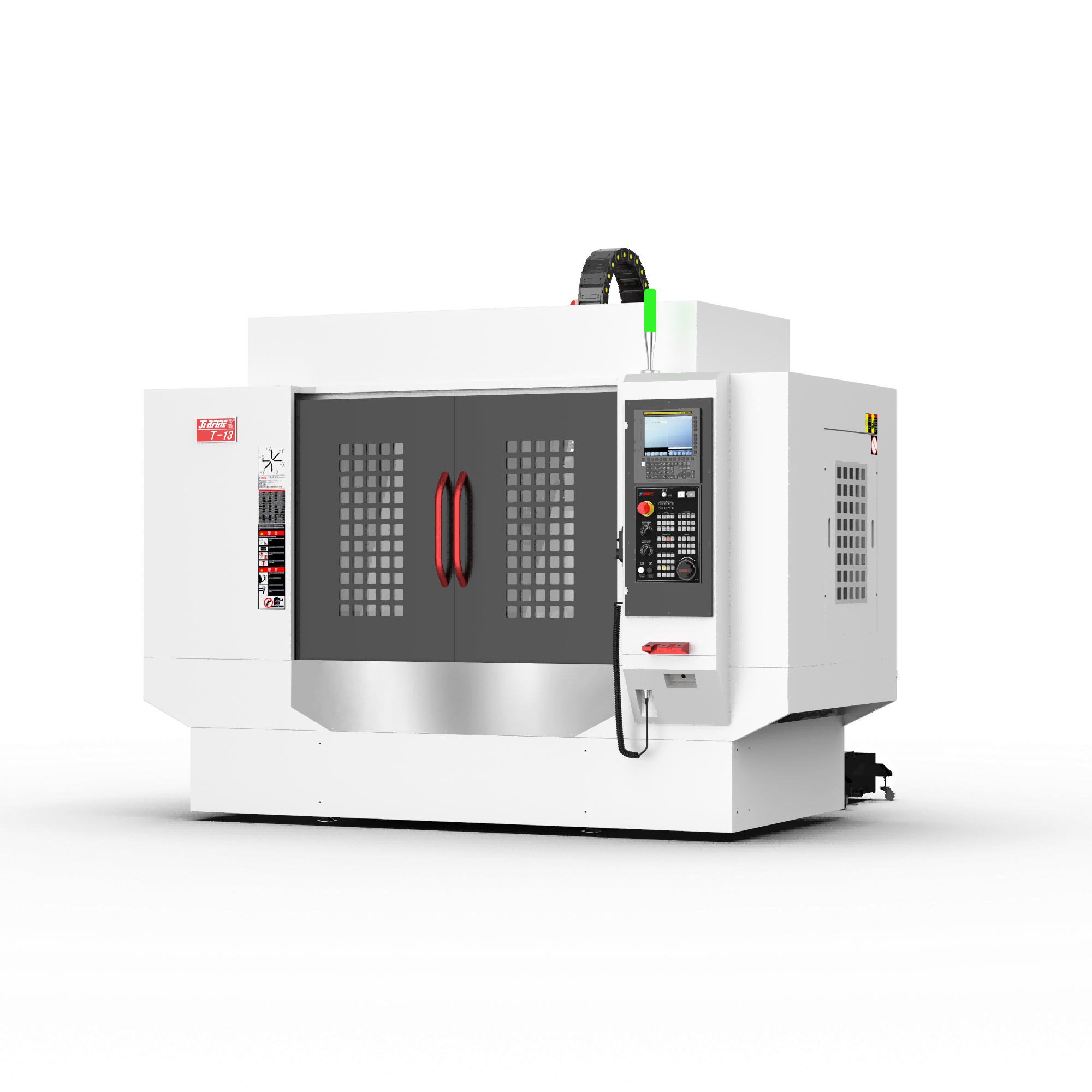

Característica

01

Golden ratio span diseño, alta velocidad y mecanizado de alta precisión está más garantizada

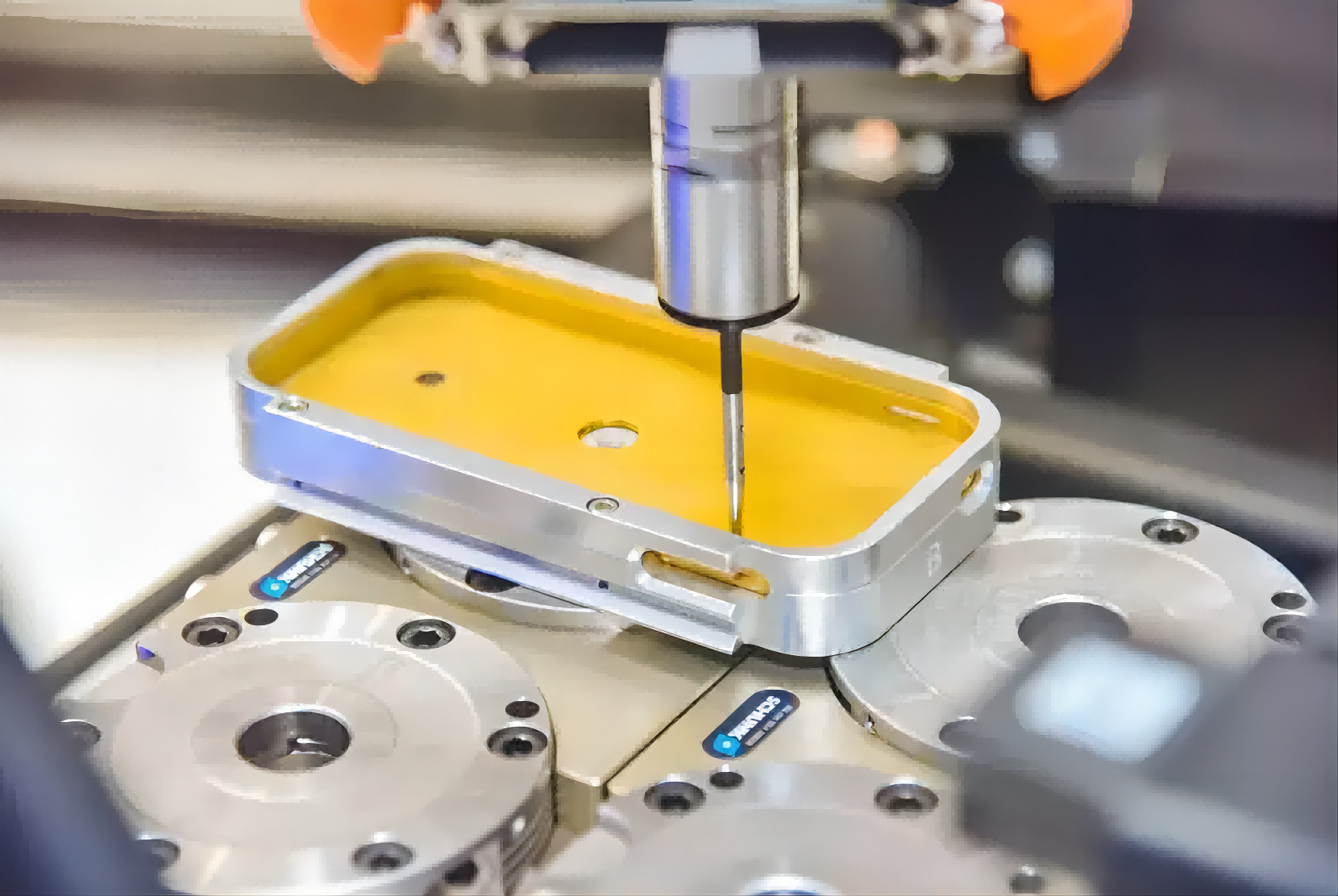

02-02

Diseño de accionamiento directo del husillo, velocidad de salida directa desde el eje del motor para obtener un efecto de roscado de alta calidad

03

El recorrido súper grande del eje X/Y rompe el dilema de que las máquinas tradicionales de perforación y roscado no pueden procesar piezas de trabajo grandes

Specifications

| Item | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 1000 |

| Y axis travel | mm | 500 | |

| Z axis travel | mm | 300 | |

| Distance from spindle nose to worktable | mm | 180-480 | |

| Distance from spindle center to column | mm | 550 | |

| Workbench | Workbench size | mm | 1100x500 |

| T-slot(sizexslot no.xspace) | mm | 14x5x80 | |

| Maximum load of workbench | kg | 400 | |

| Spindle | Speed | rpm | 12000 |

| Spindle taper | # | BT30 | |

| Transfer method | # | Direct drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 48/48/48 | |

| Precision | Positioning precision | mm | 0.008/0.005/0.005 |

| Repeatability | mm | 0.005/0.003/0.003 | |

| Tool changing system | Number of tools | pcs | 21 |

| Max tool weight | kg | 3 | |

| Max tool length | mm | 250 | |

| Tool diameter (full tool/neighbor empty tool) | mm | 100/140 | |

| Tool magazine form | # | Jaw type (servo) | |

| CNC system | Control system | # | FANUC 0I-MF |

| Spindle motor power | kw | 3.7/13 | |

| Three-axis motor power | kw | 2.7/2.7/3.0 | |

| Others | Required air pressure | kgf/cm3 | 6 |

| Electricity demand | KVA | 20 | |

| Net weight | kg | / | |

| Dimensions(LxWxH) | mm | 2460x2860x2420 |